Chromatography systems are often defined by their pressure characteristics. Common acronyms like LP or HPLC are used to refer to low pressure and high pressure liquid chromatography, respectively. Systems that operate at pressures <50 psi (~3 bar) are categorized as low pressure chromatography systems. Low pressure chromatography is often used for simple protein separations that do not require high resolution. Low pressure systems range from basic to semi-automated and can be equipped with gradient capabilities, detectors, valves, and fraction collectors.

This section describes low pressure chromatography systems, their advantages, general considerations, set up and flow path, and provides some answers to common questions.

Related Topics: Medium Pressure Chromatography Systems and Gravity Chromatography.

Page Contents

Low pressure systems are ideal for the purification of recombinant tagged proteins and work with most pre-packed columns. Bio-Rad offers a suite of products for low pressure chromatography, including the BioLogic™ LP chromatography system (low pressure chromatography systems), Profinia™ protein purification system (affinity chromatography protein purification system), Econo™ gradient pump kits and the Model EP-1 Econo™ pump.

If you would like to determine the kind of purification system best suited for your needs, use our chromatography system configurator.

Simplicity

Lower pressure systems are inherently simpler to use, easier to maintain, less prone to leaking, and the design of the pump allows for quick and easy priming. Many of the fluidics connections are quick-release such as luer fittings. The tubing is often silicone rubber which is easy to cut and piece together with barbed fittings. For pressures >25 psi, tubing ties or clamps are recommended on the barbed fittings.

Siphon Strength

The design advantage of low pressure pumps allows liquid to be drawn up, or siphoned up, significant heights. This is especially useful when the buffer or sample is in a large container that cannot be lifted easily onto the bench. Higher pressure systems often use check valves in their pump design and proper operation of these check valves requires a neutral or positive (head) pressure before the pump. Therefore, higher pressure pumps cannot siphon liquid up more than a few inches

Cleanability

Most low pressure systems that use peristaltic pumps are quite easy to clean. The tubing can be flushed and autoclaved or simply discarded and replaced.

Backpressure

Low pressure systems can only force liquid along a flow path if the pressure capabilities of the system exceed the resistance or backpressure after the pump. The following factors will increase backpressure and should be considered in the set up and use of the system:

- Tubing inner diameter and/or connections

- Lower temperatures like those in cold rooms or refrigerators. Low temperature increases the viscosity of the solvent or buffer and thereby increases the backpressure. This will be more pronounced with buffers containing a high concentration of dissolved salts (e.g. 1M NaCl)

- Certain buffer gradients

- Smaller beads or lower porosity in the chromatography media

Pulsation

Pumps (such as peristaltic pumps) that produce lower pressure flows can often produce pressure pulsations as well. In general, pulsations will not adversely affect separations at lower pressure. Some exceptions are:

- Small bubbles present in the detector flow cells. Bubbles can expand and contract with the pressure pulsations causing changes in the UV and/or conductivity signals which might look like interference or 'ghost' peaks

- Sample volume is large and highly concentrated. Pressure pulsations can cause mixing within the flow path which can result in precipitated protein

- High resolution size exclusion (gel filtration) purification. Size exclusion relies on a stable flow rate and consistent rate of diffusion into and out of the pores of the chromatography media. Pulsations can be disruptive to this process

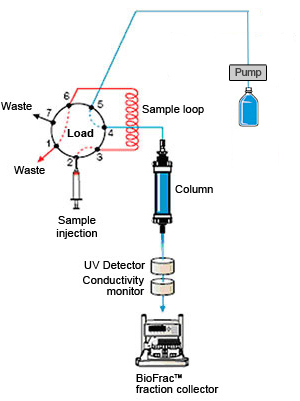

Low pressure systems follow a simple flow path: buffer reservoir to pump, to injection valve, to column, to UV detector, to conductivity monitor, to pH monitor, to fraction collector or outlet valve. A common variation of low pressure systems is to use the buffer inlet to manually load sample directly through the pump. This is especially useful if the sample is in a large, dilute volume. As mentioned above, the tubing and pumps used in low pressure chromatography are easy to clean or replace so clogging the pump and cross contamination are not a concern. Bio-Rad offers a suite of options for low pressure chromatography from the Econo Gradient System to a fully featured BioLogic LP System.

Low pressure setup and flowpath.